We are a digital agency helping businesses develop immersive, engaging, and user-focused web, app, and software solutions.

2310 Mira Vista Ave

Montrose, CA 91020

2500+ reviews based on client feedback

What's Included?

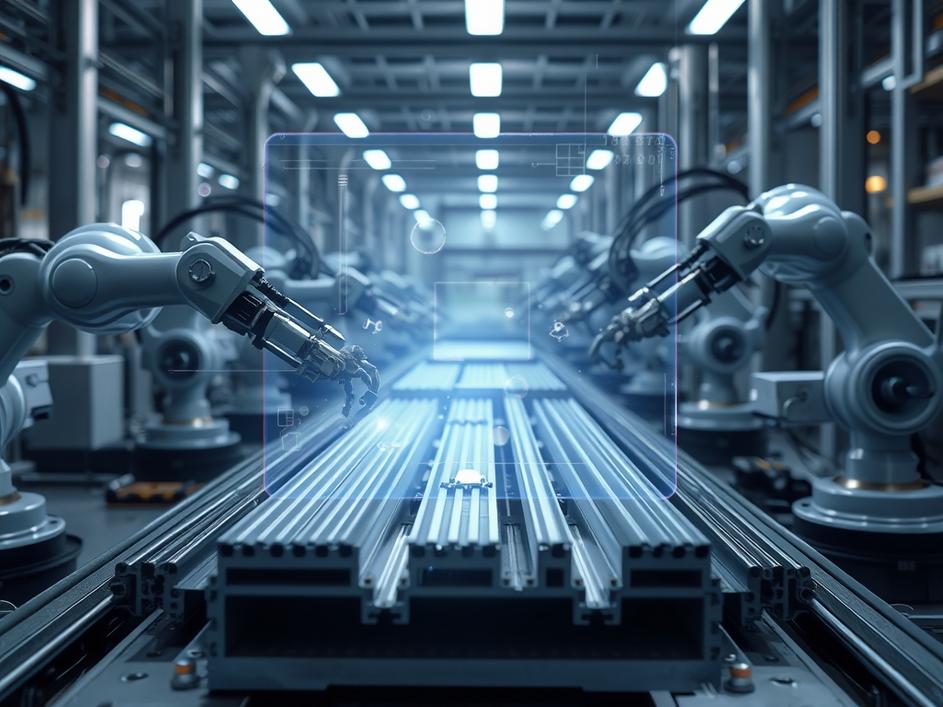

ToggleIn the world of manufacturing, sometimes the smallest details make the biggest difference. Think about the tiny aluminum parts that go into everything from medical devices to complex electronics. These miniature extrusions, often no thicker than a human hair, demand absolute perfection. For decades, companies like Minalex have mastered the art of creating these intricate metal forms. But even with years of expertise, ensuring every single piece is flawless, especially at high production speeds, is a monumental task. This is where innovation steps in. Minalex, known for its leadership in these delicate aluminum creations, is now teaming up with Dunaway to bring advanced visual AI into their process. It’s a move that promises to change how they see and ensure quality, bringing a truly high-tech boost to traditional craftsmanship.

Imagine trying to check thousands of miniature aluminum rods or profiles every hour, each one needing to be exactly right. The challenges are huge. Even the slightest scratch, a tiny deviation in shape, or a microscopic surface imperfection can render an entire batch unusable for sensitive applications. Human inspectors, no matter how skilled or dedicated, can only do so much. Fatigue sets in, small flaws get missed, and the sheer volume of parts makes consistent, perfect inspection nearly impossible. This can lead to wasted materials, production delays, and higher costs. For Minalex, whose reputation rests on delivering ultra-precise components, finding a way to overcome these “tiny troubles” was not just an improvement; it was a necessity to maintain their edge and meet the growing demands for increasingly complex and smaller parts across various industries. They needed something faster, more consistent, and utterly tireless.

This is where visual AI comes into play, acting like an unblinking, hyper-focused eye. Dunaway’s specialized AI platform is designed to look at these miniature extrusions with an incredible level of detail, far surpassing what the human eye can achieve, especially over long periods. Think of it as a super-smart system that learns what a perfect part looks like, then continuously scans every single piece as it comes off the line. It can spot minuscule defects – a hairline crack, an imperceptible bend, or a subtle surface irregularity – in a fraction of a second. This isn’t just about finding mistakes; it’s about learning patterns. The AI can identify early warning signs in the manufacturing process, allowing Minalex to adjust things quickly, preventing entire runs of faulty products. It makes quality control proactive rather than reactive, meaning fewer errors from the start and a much higher standard of output without slowing down production.

The partnership between Minalex and Dunaway isn’t just a story about one company improving its products; it’s a clear signal for the future of manufacturing everywhere. This isn’t some far-off science fiction concept; it’s happening now, showing how practical AI can be for even the most traditional industries. Imagine applying this “smart vision” to other areas where precision is paramount – electronics assembly, medical device manufacturing, or aerospace components. This move sets a precedent, proving that integrating advanced AI tools can drastically elevate quality standards, reduce waste, and boost efficiency across the board. It encourages other businesses to look beyond conventional methods and consider how intelligent systems can complement their existing skilled workforce. It’s about building smarter factories that can adapt, learn, and consistently deliver excellence, pushing the boundaries of what’s possible in product design and reliability.

Some people worry that machines and AI will simply replace human jobs. But what Minalex is doing with Dunaway shows a different story: one where technology enhances human capabilities rather than displacing them. Instead of monotonous, error-prone manual inspection, human engineers and quality control specialists can now focus on higher-level tasks. They can analyze the data the AI collects, troubleshoot complex issues identified by the system, and innovate new processes or product designs. The AI takes over the repetitive, detail-intensive tasks, freeing up human talent to engage in problem-solving, creative thinking, and strategic development. This collaboration creates a more efficient, less wasteful, and ultimately more rewarding work environment. It highlights a future where the unique strengths of both humans and intelligent machines are combined to achieve outcomes that neither could reach alone, driving industries forward with unprecedented precision and consistency.

The collaboration between Minalex and Dunaway marks an exciting milestone in precision manufacturing. By integrating cutting-edge visual AI, Minalex isn’t just making better miniature aluminum extrusions; they’re redefining what “perfect” means in the industry. This is more than just a technological upgrade; it’s a strategic embrace of innovation that positions them firmly at the forefront. It shows how even deeply rooted manufacturing processes can benefit immensely from smart technology, leading to superior product quality, reduced operational costs, and faster development cycles. As industries continue to demand higher levels of precision and reliability, partnerships like this illuminate the path forward, demonstrating that the future of manufacturing is not only intelligent but also crystal clear, offering a future where excellence is not just aimed for, but consistently achieved, one tiny, perfect extrusion at a time.

Comments are closed